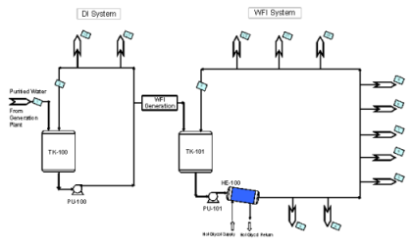

From this webpage a deterministic / stochastic model to simulate volume and schedule uncertainties of industrial size Deionised Water (DI) and Water for Injection (WFI) or WFI only can be downloaded as a zipped Excel file. The model is programmed in Visual Basic for Applications (VBA), which is part of the standard version of Excel 2003. The model utilise discrete-event simulation to calculate the demand profile from the distribution system and a continuous simulation to find the variation of the level in the storage tank over the simulation time horizon. The Monte Carlo method is used to solve the demand profile of the stochastic model. The proposed program may be utilised to size or analyse the performance of other utilities in the chemical industry such as heat transfer media, steam, etc.

The operating performance of Deionized and Water for Injection (DI/WFI) distribution systems can be difficult to analyse due to the highly variable demand that is drawn from these systems; a situation compounded by schedule uncertainties. This model contains a Fuzzy Logic (FL) model of a typical DI/WFI system simulating schedule uncertainties in the opening and closing events of the off take valves based on operator behaviour e.g. tiredness of the operators. The model utilises discrete-event simulation to calculate the demand profile of the distribution system and a continuous simulation to compute the variation of the level in the storage tank.