UV-emitting LEDs, the future looks bright!

Several members of the UV4Plants Association attended the “Joint International Conference on UV-LED Technologies and Applications” (ICULTA-2018) taking place in Berlin from April 22 to 25, 2018.

Indeed, UV-emitting LEDs are of considerable interest for plant UV-researchers, as well as for the horticultural industry. Rather than a talk-by-talk summary of the conference, this short report gives you an update on the state-of-the-art in UV-LED technology, and an overview of key areas where advances can be expected in the next few years.

ICULTA-2018 was jointly organised by the “International Ultraviolet Association” (IUVA) and the German Research and Development consortium “Advanced UV for Life”. IUVA (http://www.iuva.org) focuses on, and facilitates, scientific and technological issues that relate to the use of ultraviolet radiation. IUVA has some 500 members across 35 countries, and this includes many industry members. The “Advanced UV for Life” consortium (https://www.advanced-uv.de) aims to develop and market new products based on UV-emitting LEDs. This consortium brings together 35 industry members and 15 R&D members, from across Germany. For ICULTA-2018 some 260 participants were registered, and around 60% of these were industry based. As a result, the programme of ICULTA-2018 contained talks relating to all aspects of UV-LEDs, ranging from fundamental aspects of LED-design, LED-testing and LED-packaging, as well as device design, and product development. Product development was focussed on a number of distinct UV-LED applications, including disinfection technology, curing and printing, phototherapy, catalysis, communication and horticulture. While some of these UV-applications are very well established (e.g. disinfection of water, air or equipment, curing and phototherapy), others are much more pioneering (e.g. use of UV in horticulture).

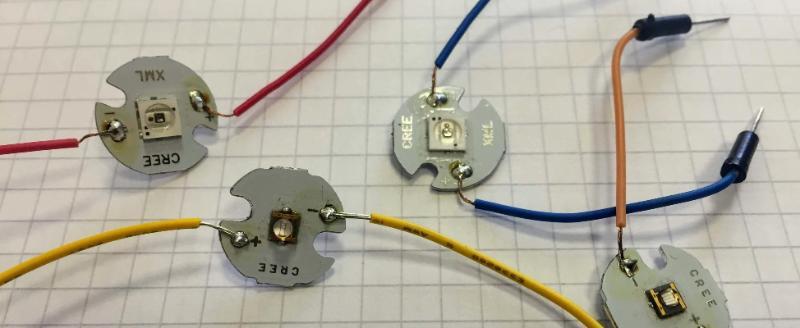

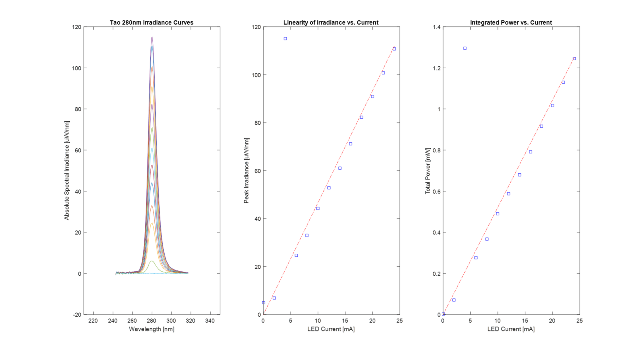

The basic principle of UV-LEDs (Figure 1) is the emission of radiation by a mixed crystal system made up of AlN, GaN and InN (aluminium nitride, gallium nitride and indium nitride, respectively, semiconductor materials). The advantages of using UV-LEDs over traditional UV sources are manifold. The LEDs are small and robust, produce little heat, can operate at low voltages, do not require toxic mercury (Hg), produce narrow emission peaks around a single wavelength, can be made to cover any wavelength in the UV spectrum, and output intensity can be electrically regulated. Emission spectra of UV LEDs of different compositions can be found in the brochure “UV LEDs for New Applications” by Jacobs et al. (2018), freely available at https://www.advanced-uv.de/. One particular application that exploits the advantages of UV-LEDs is the development of a wearable device for phototherapy (e.g. used to treat psoriasis or eczema). Such lightweight devices do not require a high power connection and cooling arrangement, and the small size of individual LEDs mean that the device can follow the contours of the body part that requires UV-phototherapy. The narrow bandwidth of UV-LEDs allows precision manipulation of chemical and biochemical processes (Figure 2), although a narrow bandwidth is not always an advantage. For example, polychromatic UV-C radiation may be more efficient for disinfection, presumably as both DNA and peptides are excited, creating a synergistic interaction.

The development of UV-A emitting LEDs is highly advanced, yet development of UV-B and UV-C emitting LEDs is more pioneering. Nevertheless, it became clear at the conference that UV-C and UV-B emitting LEDs can now be obtained from several suppliers, and that it is possible to obtain a range of LEDs emitting different UV-B or UV-C wavelengths. For example, talks at ICULTA-2018 referred to 294, 298, 305, 310, 315, 320, and 325nm UV-LEDs. However, not all is well at this stage, as the efficiency and output of these LEDs is still very low. In this context Haitz’s law is of interest as it states that every decade LED optical power increases 20-fold, while prices come down 10-fold. Although it is still early days in UV-LED development, early trends are consistent with Haitz’s law. At present, the light extraction efficiency of UV-LEDs is typically around 5% for UV-B and UV-C LEDs, although in some reported cases this was closer to 1-2%. In comparison, e.g. blue LEDs have an efficiency of 80% and higher.

Improving light extraction efficiency of UV-emitting LEDs is closely linked to temperature control. Thus, thermal management is a key consideration when developing devices equipped with UV-emitting LEDs. Another consideration is that, especially for applications in plant biology, exposure to humidity needs to be avoided. So, encapsulation of UV-emitting LEDs is another important topic, whereby the transmitting properties of polymers over the life-time of the LED are of particular interest. In this context, several speakers commented that replacement of traditional Hg-based UV sources by UV-LEDs will in many cases require the entire redesign of devices, and this applied specifically to well established devices such as disinfection devices currently relying on Hg-UV sources.

So, should we all dump our old UV lamps and go for UV-emitting LEDs? The answer to this question might well be “yes, but not yet”. UV-LED technology is rapidly advancing, but serious hurdles remain. To facilitate applications of UV-LEDs the emission spectrum, and optical output and spatial radiation pattern of LEDs should change as little as possible over the lifespan of the UV-emitting LED. Life span is given as the L50, the time by which the LED emits just 50% of the initial intensity. Optical performance of some UV-emitting LEDs can start decreasing after 100s of hours of operation in some cases, but in excess of 10.000 hours in other cases (the estimated L50 for a 310nm LED was estimated around 20.000h). Another serious consideration is LED tolerances, as wavelength peaks can vary as much as ± 5nm. Clearly, not all UV-LEDs that emit nominally the same wavelength are equal, and there are high variances between the products of various manufacturers. Thirdly, cost is still prohibitive for the commercial use of UV-emitting LEDs in horticulture. However, at ICULTA-2018 presentations by Prof. Marcel Jansen (Cork), Prof. Annamaria Ranieri (Pisa) and Dr Melanie Wiesner-Reinhold (Grossbeeren, Berlin), all showed the potential benefits of UV-exposure of crops for both growers and consumers. Dr Wiesner-Reinhold reported how levels of metabolites are regulated in a number of crop species exposed to UV radiation emitted by either 290nm or 307nm UV using a UV-B LED module developed by the Leibniz Ferdinand Braun Institute, Berlin, Germany. An advanced prototype was shown during the conference and is presented at https://www.fbh-berlin.com/prototype-engineering/prototypes. The clear impact of LED-emitted UV radiation on the plants demonstrated that UV-LEDs are powerful enough to alter plant metabolism, and UV-LEDs are becoming a realistic perspective for plant biology researchers. The horticultural industry will need cheap, long-lived and reliable UV-emitting LEDS (which are not yet available), but conversely the horticultural industry can reduce LED costs by generating a large scale demand which results in production efficiencies of UV-B emitting LEDs. So, watch this space!

For those with an interest in UV-LEDs, the next IUVA world congress will take place in February 2019 in Sydney, Australia (see http://www.iuva.org/).

reference: Jacobs K, Mertsch A, Hübener N (2018), Advanced UV for Life – UV LEDs for new applications, status and perspectives. Berlin. PDF download from https://www.advanced-uv.de/.

Report by Marcel Jansen1 and Andreas Albert2

1School of Biological, Earth and Environmental Sciences, University College Cork, Ireland https://orcid.org/0000-0003-2014-5859

2Research Unit Environmental Simulation, Helmholtz Zentrum München, Deutsches Forschungszentrum für Gesundheit und Umwelt GmbH, Neuherberg, Germany https://orcid.org/0000-0002-0582-2674

UV LED for Crops Research Group

Contact us

School of Biological, Earth and Environmental Sciences, University College Cork, Distillery Fields, North Mall, Cork, Ireland, T23 TK30