| Code | PE6022 |

|---|---|

| Duration | 12 weeks |

| Teaching Mode | Part-Time. See Additional Teaching Mode Information for more info. |

| NFQ Level | Level 9 |

| Fees | €1,000 See Fees and Costs for full details. |

| Closing Date | 05/01/2026 |

| Venue | Blended delivery. |

| Credits | 5 |

| Start Date | 16/01/2026 |

Outline

Module Goal

To provide a framework for the design of an aseptic manufacturing facility in the production of pharmaceuticals.

Module Content

- Overview of the biopharmaceutical industry, aseptic manufacturing production facilities design

- Overview & design philosophy, sterilisation and disinfection (thermal and non-thermal), lyophilisation, facility architecture and layout, air classification, ventilation, air conditioning & HEPA filtration, water, surface finishes, pressure, barrier isolation technology, personnel, clothing, design considerations in the rest of the facility, regulatory framework and issues.

Additional Teaching Mode Information

- 1 x 4hr(s) lectures

- 1 x 8hr(s) tutorials

- 1 x 12hr(s) problem-based learning

In person lecture/tutorial date

| Date | Time | Location |

|---|---|---|

| Saturday 25th of January | 1pm - 5pm | Electrical Engineering Lecture Theatre 2 |

| Friday 22nd of February | 2pm - 8pm | Electrical Engineering Lecture Theatre 2 |

Practicalities

Continuous Assessment - 100 marks

| Assignment | Short Questions | 30 |

| Assignment | Design Exercise | 70 |

Why Choose

On successful completion of this module, students should be able to:

- Present an overview of the biopharmaceutical industry and the manufacture of biopharmaceuticals.

- Identify the major design and regulatory issues associated with the design and operation of an aseptic manufacturing facility for the production of pharmaceuticals.

- Outline the implementation of a suitable sterilization, disinfection, lyophilisation regime in an aseptic processing facility.

- Design a suitable aseptic facility services and utilities including air classification, ventilation, air conditioning & HEPA filtration and water.

- Propose an outline design of an aseptic manufacturing facility which includes design philosophy, facility architecture and layout and surface finishes.

- Identify appropriate personnel clothing and procedures for working in an aseptic manufacturing environment.

Requirements

Applicants must have a BE (Hons) or BEng (Hons) Degree or equivalent engineering qualification, with a minimum Second-Class Honours Grade II, OR a level 8 BSc degree, with a minimum grade Second Class Honours Grade II, where the BSc graduate has a recognised qualification in process or Chemical Engineering (e.g. Diploma in Process and Chemical Engineering at UCC or equivalent). However, applicants with equivalent academic qualifications and suitable experience may be accepted subjected to the approval of the Programme Director under Recognition of Prior Learning (RPL), In all cases, the course of studies for each application must be approved by the Programme Director.

Fees and Costs

€1,000

How To Apply

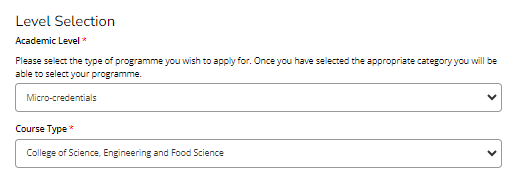

Please select the following options during your online application (once you have created your profile)

Start a new Micro-credentials application by selecting as below

In the application level tab select the options below and then select the programme/module you'd like to apply for