The future of dairy? 3D printing of Cheese

One of the most exciting areas of food processing globally at present is 3D printing, with food companies, chefs and consumers alike seeing great potential in the ability of this technology to tailor and personalize food shapes, structures and formulations using this highly innovative technology. The principle of 3D printing is that a material is extruded (printed) through a suitable nozzle onto a flat surface, with the position of the nozzle being controlled by a computer into which a particular target shape or configuration has been programmed, such that layers of material can be built up into a vast range of shapes and designs, once the material being printed has the property of solidifying enough on printing to retain its shape and position.

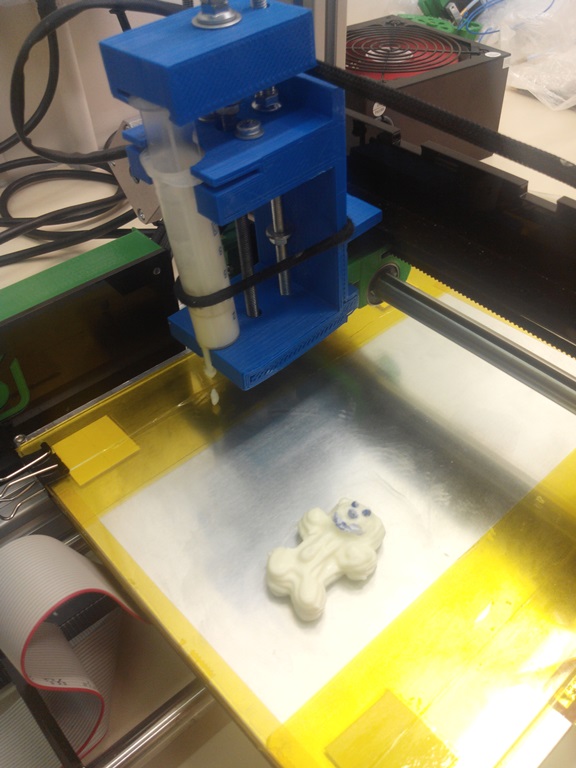

3D printing of plastics and other non-food materials has shown the ability to design and create an incredible range of objects in an inexpensive and technologically simple and inexpensive manner. In the food area, initial successes have concerned printing chocolate and confectionary, but researchers at the School of Food and Nutritional Sciences at UCC have demonstrated for the first time that dairy products can also be good materials for customized printing. In a paper published in February 2017 in Journal of Food Engineering, they reported the successful printing of processed cheese, and characterized the changes in product texture induced by the printing process.

The catalyst for this work was a question from a cheese producer to Professor Alan Kelly about the idea that in the future kitchens (at home or in restaurants) could be using 3D printers which would need raw materials and recipes, one of which could be cheese. This sparked off a very productive collaboration with Dr Alan Morrison of the School of Engineering at UCC and Professor Joe Kerry of School of Food and Nutritional Sciences, a lot of practical work done by three visiting French undergraduate students who are lead authors on the final paper. In initial stages of the project, lots of cheese types were tested, but processed cheese was found to work best.

A short video on the work can be seen at: https://www.youtube.com/watch?v=55f_oRXzFPU

The team are now working on more systematic model systems which are much less complex than cheese, for example using mixtures of milk proteins at present to build a product, such as a high-protein snack, from the basics up, and designing recipes which might work best for 3D printer.

All results to date show 3D printing to be a hugely exciting potential technology for food processing, with enormous potential to explore and innovate. This is demonstrated by the fact that, in recent weeks, the UCC work has drawn media and social media attention from around the world, showing the public interest in the technology. This has led to much discussion and new avenues for the work, consistent with the open-source/open-innovation principles which have characterized the development of 3D printing, whereby progress has been made most rapidly by sharing and discussing studies, successes and failures among the growing community of interested scientists, chefs, engineers and the public.

School of Food and Nutritional Sciences

Contact us

School of Food and Nutritional Sciences, Room 240 Food Science Building, University College, Cork