- Home

- About

- Student Led

- Research Informed

- Practice Focused

- Resources

- News

- Green Campus Podcasts

- Case Studies

- Green Labs Community

News

ORB HEAT PUMP PROJECT

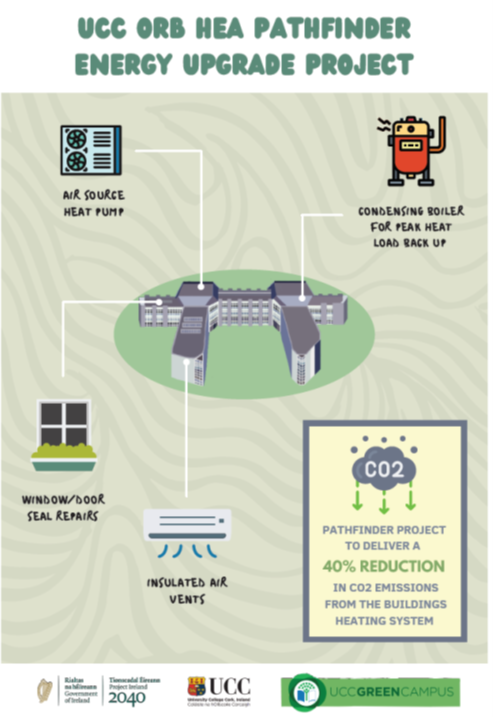

In 2020 the Higher Education Authority (HEA) launched a pathfinder program under Project Ireland 2040. The pathfinder program was set up to find strategic pathways for energy efficiency and decarbonisation programs within higher education buildings. UCC applied for and obtained grant funding under the program for the decarbonisation of the O’Rahilly building (ORB) heating systems.

The objective of the project is to demonstrate the retrofitting of a low temperature Air Source Heat Pump (ASHP) into a 1990’s building without the need for significant intervention on the building fabric or heating system arrangements.

The new heating arrangement will:

· Utilise the ASHP to provide at least 56% of the buildings annual heating demand.

· Reduce the heating load by 49%, when compared to the existing heating plant.

· Reducing the carbon emissions of the heating system by 40%.

· Maintain comfortable indoor conditions for building users.

About the building.

The 5 storey building, built in the late 1990’s, measures 11,812m2 and is located on the Main Campus of UCC and houses offices, classrooms, computer labs and a café.

The building consists of 2 main Blocks, Block A and Block B. Each block is serviced by 2 separate plantrooms with each block having its own heating network, wet services and electrical distribution.

The building archetype is that of a 1990 mixed-use building and is laid out in offices (single to 3-4 persons) and classrooms ranging from 10 – 40 persons.

Overall air tightness is generally good and the largest source of heat loss comes from the opening of office / classroom windows in a naturally ventilated building, the automatic opening vents in the Atrium, ground floor emergency exit doors and the main entrance lobby.

Existing Heating Network

The existing low pressure hot water system is supplied by 6 gas boilers with a combined rating of 3,780 kW and is split up into 2 plantrooms. Plantroom 1 feeds the heating system in Block A and plantroom 2 feeds the heating system in Block B.

Block A plantroom boilers.

Heat is distributed throughout the building via a piping network. The heating supply to each floor section is controlled by a 3 port valve that limits the rate of heat supplied to the floor area, depending on the temperature reading from a temperature transmitter fitted in the area.

A separate constant temperature heating circuit in Block A and Block B serves heating to the Air handling units across the building.

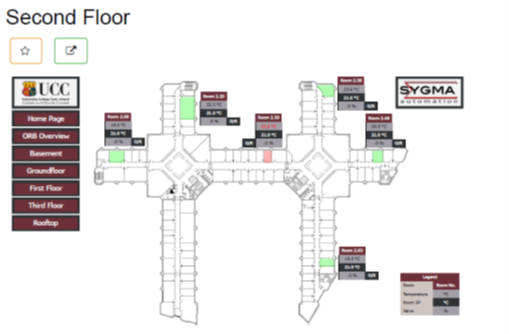

BMS Screen shot of 2nd Floor Layout

Energy Saving Opportunities

The following energy saving opportunities (ESO’s) apply to this project.

| ESO |

Summary of scope |

| Heat Generating Plant Upgrade |

Installation of a new 200 kW ASHP and 2 off 475 kW gas boilers plus low loss headers and associated controls to replace 6 boilers. |

| Pump Upgrades |

Replacement of 5 fixed speed pump sets with pressure controlled, BACnet enabled pump sets. |

| 3 Port Valve modifications |

Installation of Differential Pressure sensor and lock off bypass ports on approx. 23 3 port valves. |

| Insulated air vents |

Installation of insulated airtight air vents in the Block A / B atria to replace existing non insulated / non air tight units. |

| Building Repairs |

Replace / repair broken window seals and handles across the building. |

Table 2 – ESO listing

If all ESO’s are implemented and the static factors were to remain valid, the expected annual consumption for the building heating system, against a baseline of 2018/19, shall reduce by 49%

| Scope |

Annual Consumption before (kWhr) – Oct – Sept |

Annual Consumption After kWh (Oct to Sept) |

Total TCO2 (Before) |

Total TCO2 (After) |

| Electrical |

0 |

85,515 |

0 |

35.8 |

| Natural Gas |

590,458 |

214,336 |

120.2 |

29.7 |

| Total |

590,458 |

299,851 |

120.2 |

65.5 |

| Heat Supplied via ASHP |

0% |

56% |

|

|

Table 3 – Estimate of Annual Consumption Before / After ESO’s.

Current Project Status

At the time of writing (August 2021) the construction stage of the project is nearing completion. The new heat pump is installed and in the final stages of getting hooked up, tested and should be ready for the start of the October heating season.

Measurement & Verification

The performance of the new heating system will be monitored over a 3 year period and the savings verified in accordance with the International Performance Measurement and Verification Protocol (IPMVP) 2016.

Thank You.

This project is made possible through the HEA pathfinder program and UCC are grateful for the support of the HEA and SEAI.

Our minor works team of Aidan O’Dwyer and Brian Walsh, with the support of our partners in Powertherm, provided the technical design and are also responsible for overseeing the tendering, installation and commissioning of the project.